.:. Mill Critical Speed .

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

WhatsApp)

WhatsApp)

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at ...

Ball Milling An efficient and ... What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . ... Rotation speed 8 .

ball milling ball speed manufacturer in Shanghai China. ball milling ball speed is manufactured from Shanghai XuanshiIt is the main mineral processing solutions.

Ball Nose milling application information. Feed, speed and diameter compensation. Recommended ball nose cutting speeds. Troubleshooting.

A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell''s inside ...

ball milling ball speed manufacturer in Shanghai, China. ball milling ball speed is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions.

Keywords: High Speed Machining, ballend milling, vibration control, Vibration monitoring during high speed milling was performed on the basis of results of.

Wet Milling. Bead Mills. DYNO®MILL; ... High Speed Mixer Mill (MM400) RotorStator Homogenizers. ... Planetary Ball Mill; Rotor Beater Mill;

The MSKSFM3 (Updated since 7/17/13) is a compact high speed vibrating ball mill for making small quantity of powder samples at easy and fast with improved vibration ...

Ball Milling Machine Manufacturers, Mill Speed An. ball milling machine manufacturers. Mill Speed is An important design aspect for perfect milling.

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Find all the manufacturers of ball mills and ... demonstrated a plethora of benefits over conventional ball milling. ... Rotational speed: 400 rpm. Ball mill is a ...

Theory and Practice for . Jar, Ball and Pebble Milling . Types of Mills . Ball and Pebble Mills: The expressions "ball milling" and "pebble milling" are

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction and Mill Speed Critical Speed needs.

What it is the optimun speed for a ball mill ? posted in Pyrotechnics: I have done a ball mill, recenly finished, but the motor has too rpms, is too fast for use ...

Quick Easy Black Powder Ball Mill ... optimum material load, and optimum milling speed. ... This is the most important factor for ball milling success.

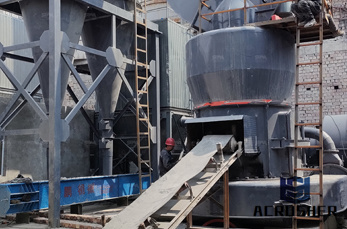

Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel ...

ball milling ball speed. Simulation of ball motion and energy transfer in a plaary between the vial wall and ball, acts on the samples to be milled.

What is a Ball Mill? A ball mill is a type of grinding mill, purposed similarly to the sag mill or other mining crushers. These machines are used to grind or mix ...

Critical Speed Of Ball Mill Calculation India. ... fraction of critical speed, ball size, ... End Milling Calculators For End Milling Applications.

Herein, we report on the solventfree Sonogashira reaction utilizing high speed ball milling. Sonogashira coupling of a variety of para substituted aryl halides were ...

51 BULGARIAN ACADEMY OF SCIENCES CYBERNETICS AND INFORMATION TECHNOLOGIES • Volume 12, No 2 Sofia • 2012 Grinding in Ball Mills: Modeling and .

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed.

Wet ballmilling route is employed to prepare sulfurcarbon nanotubes composites. The influences of solvents, including ethanol and chloroform, on the structure

WhatsApp)

WhatsApp)